Pre Engineered Buildings (PEB)

Design of (PEB) Pre Engineered Buildings Cost

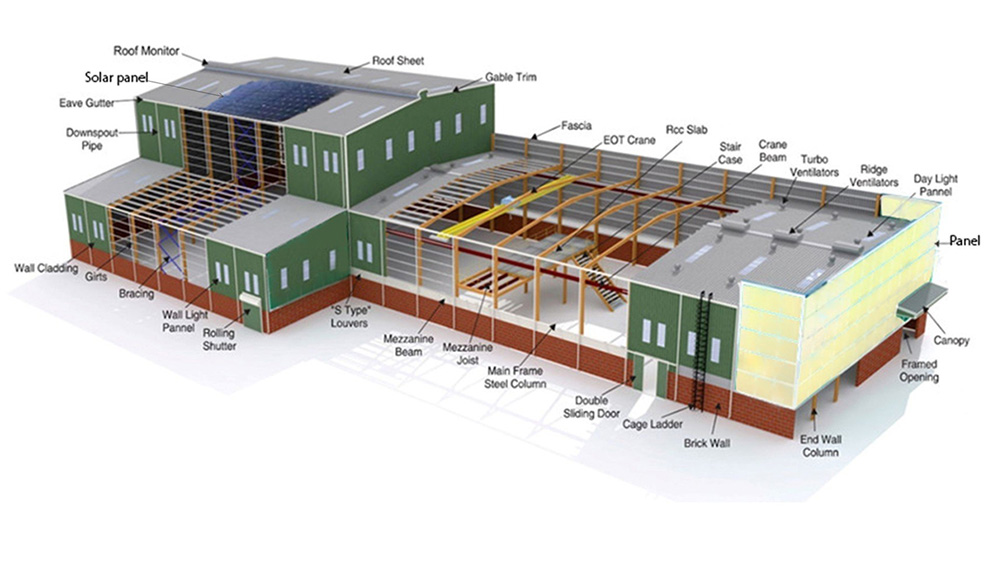

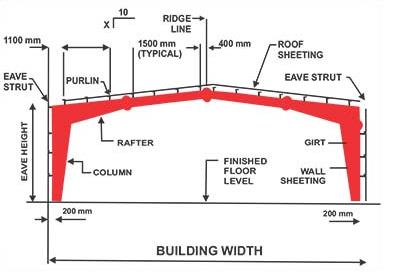

Pre Engineered Buildings (PEB) revolutionize construction with efficient design and rapid assembly. These structures integrate steel framing components fabricated off-site, tailored to project specifications, ensuring precision and cost-effectiveness. PEB design employs advanced software for structural analysis, optimizing material usage, and enhancing overall strength. The versatility of PEBs accommodates diverse applications, from warehouses and industrial facilities to commercial complexes. The streamlined construction process reduces on-site labor and time, minimizing project timelines. PEBs are sustainable, offering energy-efficient solutions with recyclable materials. Their adaptability, durability, and eco-friendly attributes make pre-engineered buildings an innovative choice for modern construction projects.

DESIGN CYCLE

The design cycle consists of the following steps:

- Set up section sizes and brace locations based on the geometry and loading specified for the frame design.

- Calculate the moment, shear, and axial force at each analysis point for each load combination.

- Compute allowable shear, allowable axial, and allowable bending stress in compression and tension at each analysis point.

- Compute the corresponding stress ratios for shear, axial, and bending based on the actual and allowable stresses, and calculate the combined stress ratios.

- Design the optimum splice location and check to see whether the predicted sizes conform to manufacturing constraints.

- Using the web optimization mode, arrive at the optimum web depths for the next cycle and update the member data file.

- At the end of all design cycles, an analysis is run to achieve flange brace optimization.

Applications :-

- Warehouse

- Petrol Stations

- Factory

- College & Schools

- Cold Storage

- Commercial Complex

Advantages :-

- Single Source Responsibility

- Reduced Construction Cost

- Fast Installation

- Quick Control

- Maintenance Free